Under the motto “be smart”, WITTMANN BATTENFELD will present to interested trade visitors top-level injection molding technology from 17 to 24 October in hall B1, booth 1204 at this year’s Fakuma in Friedrichshafen.

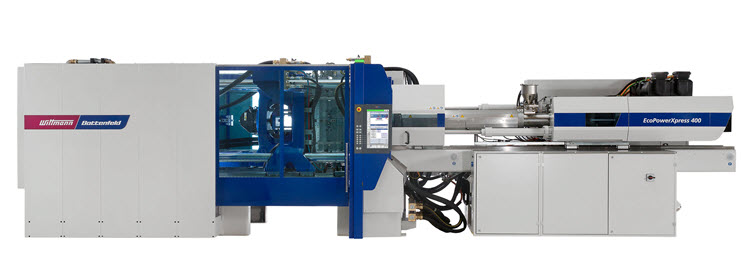

The new EcoPower Xpress – shown for the first time as a prototype at the K 2016 – was developed to series production level in the course of this fiscal year and will be available on the market in the clamping force sizes of 400 and 500 t from the autumn of this year.

The new EcoPower Xpress is a high-speed, all-electric machine model primarily geared to the requirements of the packaging and thin wall industry. The highly dynamic drive axes for injection as well as closing and opening of the EcoPower Xpress are designed for fast movements and ultimate control accuracy. Moreover, extremely high energy efficiency is achieved by using servo drives.

At the Fakuma, WITTMANN BATTENFELD will demonstrate the functionality of this machine model on an EcoPower Xpress 400/3300+ manufacturing HDPE closing caps within a cycle time of 2.7 seconds in a 96-cavity mold supplied by the French company Plastisud. The caps will be cooled with the cap cooler from Eisbär, Austria and then deposited in boxes.

For more information, please visit www.wittmann-group.com