Teknor Apex Announced New Nylon Compound with Faster Molding Cycles

Teknor Apex, a global leading custom compounder of plastics, announced a next-generation polyamide 6,6 compound, which overcomes cycle-time limitations of earlier workhorse grades, enabling injection molders of fasteners and similar parts to meet the same product performance requirements while increasing productivity and plant capacity.

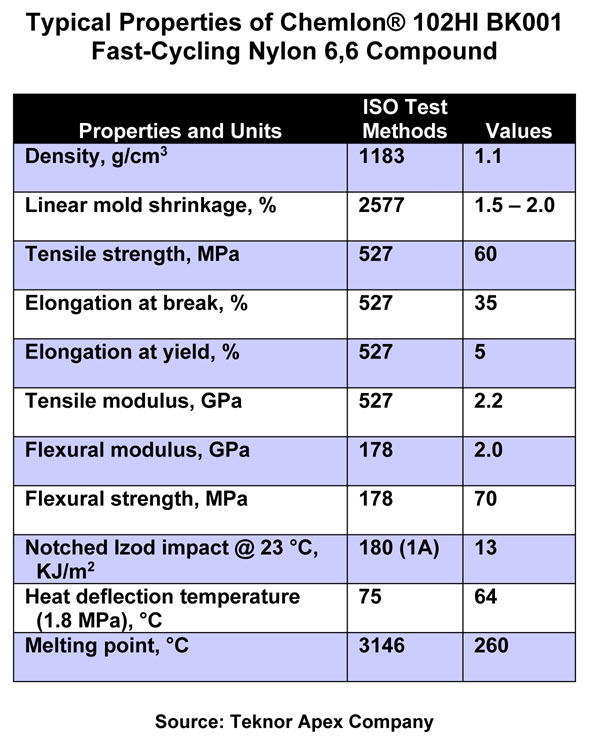

The new Chemlon® 102HI BK001 is the first compound in what will be a new suite of nylon products for fastener applications. It provides the same performance properties as an established workhorse grade, Chemlon 104H, but in gate-freeze tests by Teknor Apex, Chemlon 102HI BK001 showed a 15% improvement versus industry benchmarks in achieving constant weight, and it did so without any impact to surface aesthetics during demolding.

In commercial-scale production by a customer using high-cavitation tooling, Chemlon 102HI BK001 demonstrated accelerated rates of crystallization. After long periods of runtime, the new material consistently out-performed competitive products. Some customers have reported up to a 9% increase in part production by switching over to the material, according to Brian Rickard, director of strategy and business development for the ETP Division of Teknor Apex.

“Many of our customers have been really tight on press time,” said Mr. Rickard. “This new product will allow them to open up additional capacity on their current equipment, either to run less overtime or to bring in-house jobs that had gone to contract molders. As a result, it provides our customers with a competitive cost advantage.”

Teknor Apex supplies Chemlon products globally and can develop custom formulations to meet specific customer requirements.

For more information about the company’s polyamide product lines, please visit at www.teknorapex.com/polyamides.