Adding 3D Visualization to its Injection Molding DFM System is the latest example of the company’s innovation and expansion in the market.

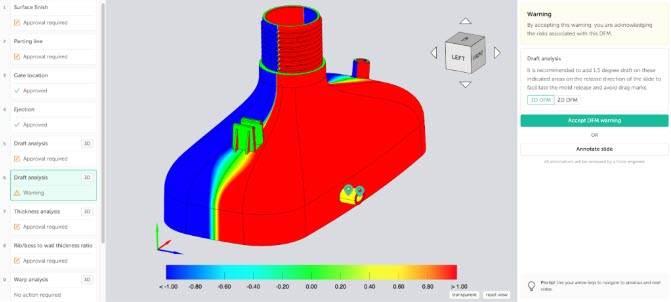

Fictiv, a San Francisco-based manufacturing bureau, has added 3D visualization to its injection molding Design for Manufacturability (DFM) system. Fictiv says it’s Digital Manufacturing Ecosystem delivers high-quality parts at unprecedented speed. According to Fictiv, the enhanced software enables complete automation of injection molding workflows, allowing clients to speed up new product design and reduce manufacturing risks and delays. The recently improved system integrates digital manufacturability issue tracking, part version control, and communication tools. 3D visualization also significantly speeds up how quickly engineering teams can request, assess, and react to injection molding DFM input and approve parts for production.

“Our goal at Fictiv is to simplify sourcing for complex injection molding tools and parts our customers need by enabling them to order quickly and easily, with minimal redesign and risk, and with expert guidance every step of the way,” said Chris Lippi, chief product officer at Fictiv. “As a technology-forward manufacturing solution, Fictiv is able to provide a digital experience that is radically more efficient and streamlined than the industry’s antiquated approach of sharing marked-up drawings over email.”

Dilan Silva, a mechanical engineer at Thermo Fisher Scientific, has over twenty-five years of experience working with vendors for custom jobs, said, “Fictiv is by far the easiest to quote, most economical, and Fictiv always delivers my parts on time. Fictiv offers many domestic and international manufacturing options to fit my budget and schedule. The quality of the parts received is exceptional, and their customer service is one of the best I’ve experienced. Fictiv is consistently evolving manufacturing technologies while driving costs and improving operational efficiency.”

What is a Design for Manufacturing (DFM) System?

Design for Manufacturing (DFM) is the process of creating products, parts, or components with how they are to be produced in mind, this should result in goods that are simple to manufacture at a reduced cost. This is accomplished by streamlining, improving, and perfecting the product design. Sometimes DFM and the abbreviation DFMA (Design for Manufacturing and Assembly) are used interchangeably.

DFM should ideally take place early in the design process, well before tooling has started. All parties involved in the project, including engineers, designers, contract manufacturers, mold builders, and material suppliers, must be included. The intent of this “cross-functional” DFM is to examine the design from all angles, including the component, sub-system, system, and holistic levels, in order to verify that it is cost-effective and optimal.

Visit www.fictiv.com for more information