Arkema, through its Sartomer Business Unit, is a pioneer in designing oligomer and monomer resins for UV-curable additive manufacturing.

Decades of supporting the 3D printing industry allow them to be uniquely positioned to build innovative engineered resins specifically designed to address the challenges of the industry. Sartomer can synthesize custom structures, deliver advanced thermosetting resins, and engage in collaborative development to bring solutions applicable to your specific need.

Arkema's UV curing technology experts give additive manufacturers the technological and market edge they‘ve been waiting for. The dedicated team of scientists and the UV curable resins Center of Excellence have enabled the success of its partners in many markets including medical, dental, electronics, and sports.

Arkema's new products:

Liquid resins for UV curing

Arkema offers an integrated line of performance liquid materials for UV-curable 3D printing, through N3xtDimension® custom formulations for customer-specific product development, N3xtDimension® engineered resins for targeted advanced performance, and Sartomer® specialty resins and additives to fine-tune end formulations.At the exhibition, Arkema will introduce two new high-performance custom formulations to extend its leading range for UV-curing:

- N3D-HITEMP062: hybrid high temperature material with excellent toughness and high HDT properties.

- N3D-CAST063: very high-resolution material, enabling matte finish so that details can be easily seen and a melting behavior during burnout for high quality castings.

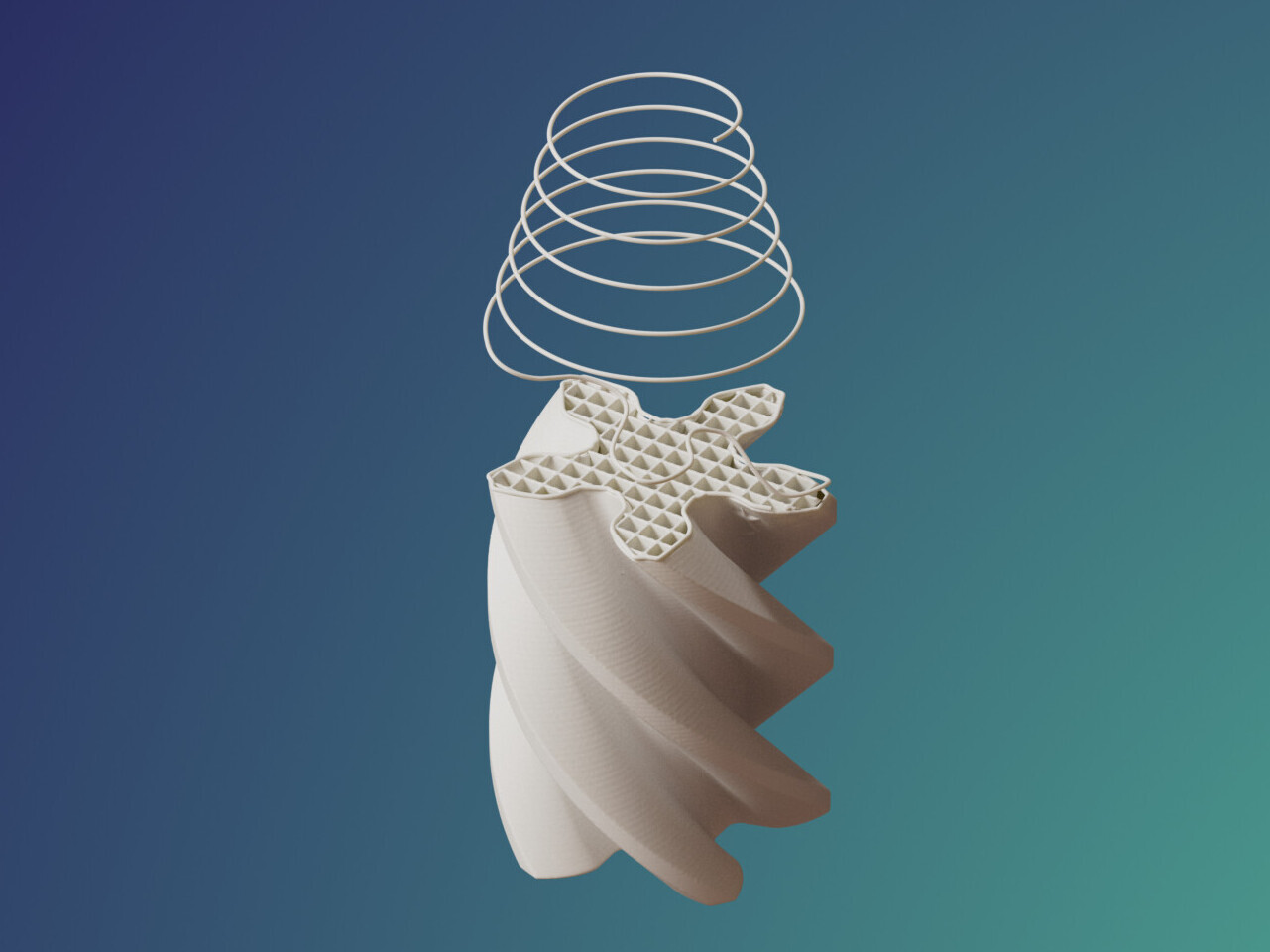

Powder bed fusion

At the exhibition, Arkema will display new solutions for powder bed fusion technologies, led by flagship brands such as Rilsan® bio-based polyamide and Kepstan® PEKK high performance thermoplastic.- Resulting from continuing collaboration on responsible manufacturing, Arkema and EOS are pleased to announce the future release of a new carbon neutral PA1101.

- Arkema and EOS will launch together a new Kepstan® PEKK powder for the EOS P 810 system, delivering higher ductility, excellent electrical insulation and higher recyclability, to fulfill the needs of high temperature applications in Oil & Gas and Electrical & Electronic markets.

Filament

With a dedicated range of advanced polymers for filament extrusion printing technologies, Arkema is pleased to announce the release of Kimya Kepstan® PEKK-SC 3D filament on Stratasys Validated Material Ecosystem, developed with our partners Stratasys and Kimya. This high performance thermoplastic filament goes beyond expectations to perform in the harshest industry environments such as end-use Oil & Gas applications like back-up rings.N3xtDimension® engineered resins

A wide range of unique liquid resins to target a specific performance. All Arkema engineered resins* are regulatory compliant, easily processable and wavelength-independent.

- Castable resin

- Impact resin

- Flexible resin

- Tough resin

- Prototyping resin

- Water-soluble resin

N3xtDimension® custom liquid resin systems

A dedicated range of Oligomers and Monomers to fine tune formulations:

- Tg

- Modulus

- Elongation

- Functionality

- Variety of chemical backbones

- Diluting power

- Reactivity

- Regulatory compliance

Product highlights

- Exceptional freedom of design and customized properties

- High resolution

- Wavelength independency

- Excellent processing

- Regulatory compliance

Printing technologies compatibility

-

SLA

-

DLP

-

MJP

-

BJ

Tailor-made resins can also be developed to meet specific custom needs.

Visit Arkema for more information