WITTMANN BATTENFELD has successfully launched its Airmould 4.0 internal gas pressure technology

- Details

- Written by AmericaPlast

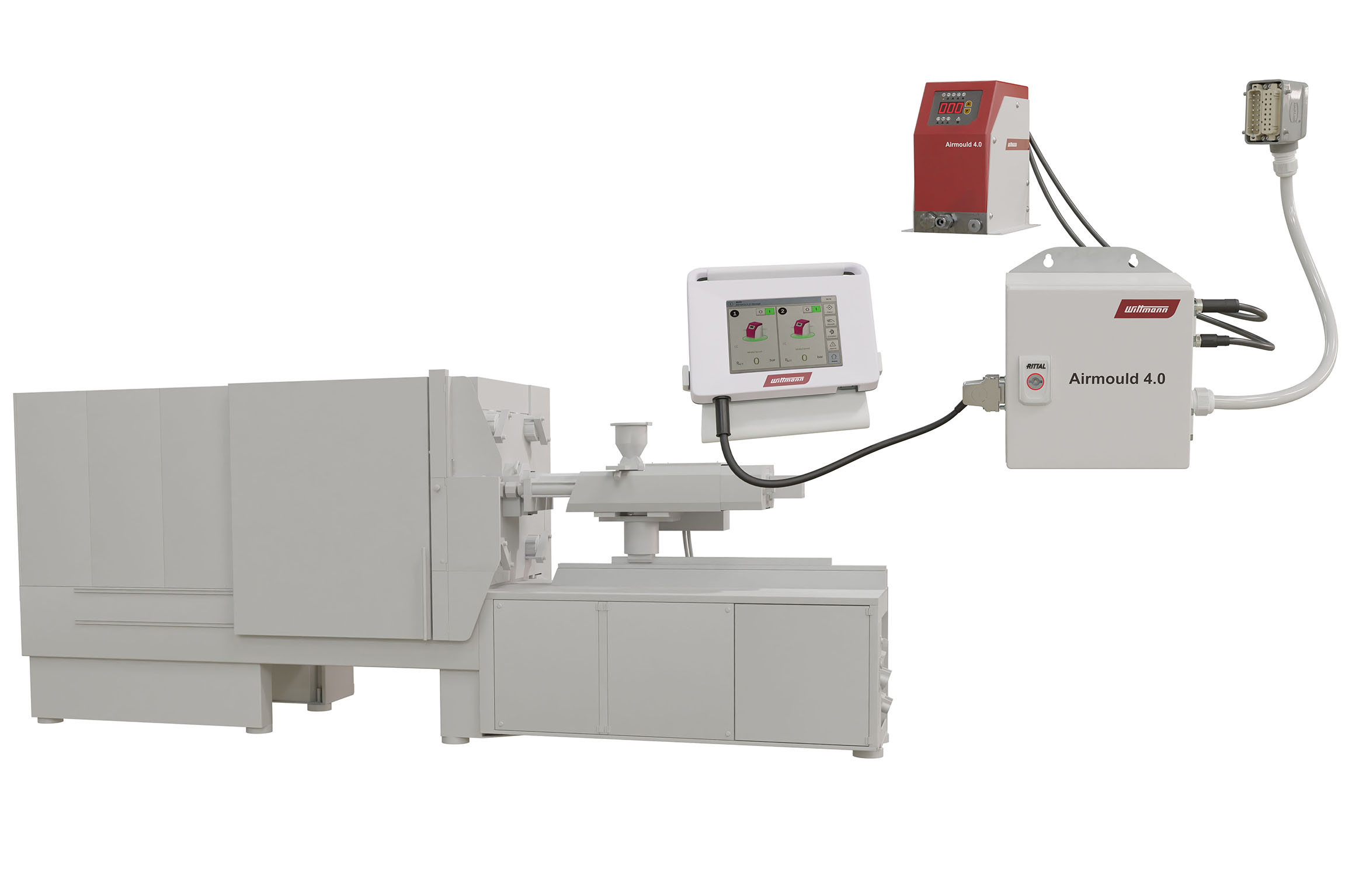

After WITTMANN BATTENFELD first presented the new generation of the Airmould internal gas pressure technology to its customers at the Fakuma 2021, the development targets have now been reached, and the competitive system has already been installed and tested on the premises of several customers. With the further development of Airmould, an even more compact and user-friendly system has been created, which meets the requirements of the industry and offers its users a number of advantages.

Airmould is WITTMANN BATTENFELD’s solution to meet the need for saving resources and for light-weight construction, and for extremely short cycle times as well. Airmould internal gas pressure technology is a process by which nitrogen is injected into a mold cavity either partly or completely filled with plastic melt to form an internal cavity structure. In this way, lightweight parts can be produced within a short cycle time and with high-quality surfaces, while also saving resources.

The new upgrade Airmould 4.0 is the only internal gas pressure system which functions without having a large control cabinet which takes up a lot of space on the production floor. The modules required are also about 15% smaller than previous versions; they are very compact and can be mounted and used flexibly on every type of injection molding machine. Another great advantage of this system is that the technical expertise for the injection molding machine and the Airmould system both come from a single source, and Airmould 4.0 is optimally designed to meet the demands of the market. In fact, Airmould 4.0 can not only be integrated into the B8 control system of an injection molding machine for easier operation, but also into machines of other brands via the uniform operating panel of the WITTMANN Group. For example, at the company`s long-standing Airmould customer Oberland MV, where Airmould 4.0 has already been in use on one of their existing machines since mid-April.

Weight reductions, component stability and minimization of sink marks are important arguments in favor of this technology, as these constitute an assurance of high-quality standards for the strong wall thicknesses of Oberland MV’s products.

Innovative and ecologically sustainable, reusable solutions have made Oberland MV a leading manufacturer of packaging for the European beverage industry. They offer their customers system solutions which include product development, manufacturing and design as well as recycling. Prizes won such as the German Packaging Award and the World Star Packaging Award are tangible evidence of the company’s commitment to high quality standards for more than 50 years.

Satisfied customers using internal gas pressure every day have confirmed to WITTMANN BATTENFELD that the development targets for Airmould internal gas pressure technology have been defined and pursued correctly. WITTMANN BATTENFELD looks forward to opening up further market potential with Airmould 4.0, especially under present production conditions, and to convincing users of the advantages of this internal gas pressure technology. It saves resources, minimize energy consumption, with a simple workcell concept, intuitive operation, low operating costs and short cycle times

Customers will receive application technology support in introducing Airmould, that may range from assistance with the machine layout right up to the pilot series in production, depending on the customer’s requirements, since WITTMANN BATTENFELD not only offers the necessary components, but also application technology support, servicing of the equipment and spare parts. Moreover, prospective buyers can see the advantages of Airmould 4.0 for themselves on Wittmann Interactive.